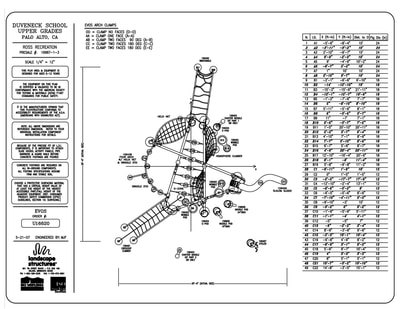

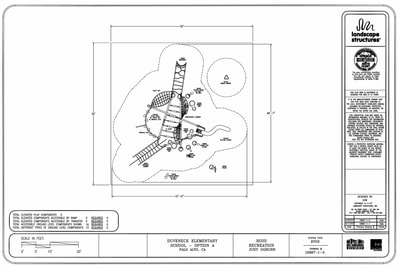

#2 - red & blue EVOS / green rubber

play equipment & surfacinglayground

100% ground level events surfacing

maintenance dates

|

notes / recommendations

|

|

notes |

|

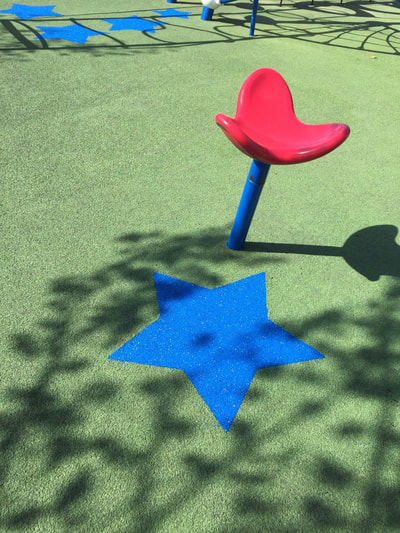

the playground rubber has deteriorated very quickly for its age.

- the quality of the rubber is not good

- it is unusual to see this much fading on 4-5 year old rubber

- based on the holes under the climber and by the spinner, it seems as though it was installed a little thinner than recommended

- routine sealing is critical

- the rubber is shared with playground #3. when that aging structure is due for replacement, all of the rubber should be considered for a recap or replacement.

- the play equipment looks brand new

- although there are some issues with the installation (see site evaluation) the equipment is holing up very well

|

|

recommendations: now |

|

- fix use zone issues (manufacturer has been contacted for recommendations)

|

|

recommendations: within next 2 years |

|

- keep an eye on the rubber for signs of cracking or holes. if any new wear and tear shows, another seal coat should probably be applied

service log

|

|

april 2018

|

|

|

maintenance

site evaluation

|